|

START HERE |

|

| Register | FAQ | PM | Events | Groups | Blogs | Calendar | Mark Forums Read |

|

Unregistered

|

||||||

| Main Forum - Helicopter Talk R/C Helicopters and the people who fly them. VENDOR TOPICS DO NOT GO HERE. Full Scale Heli threads go in OT please |

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

#21 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2012

|

Heyho guys!

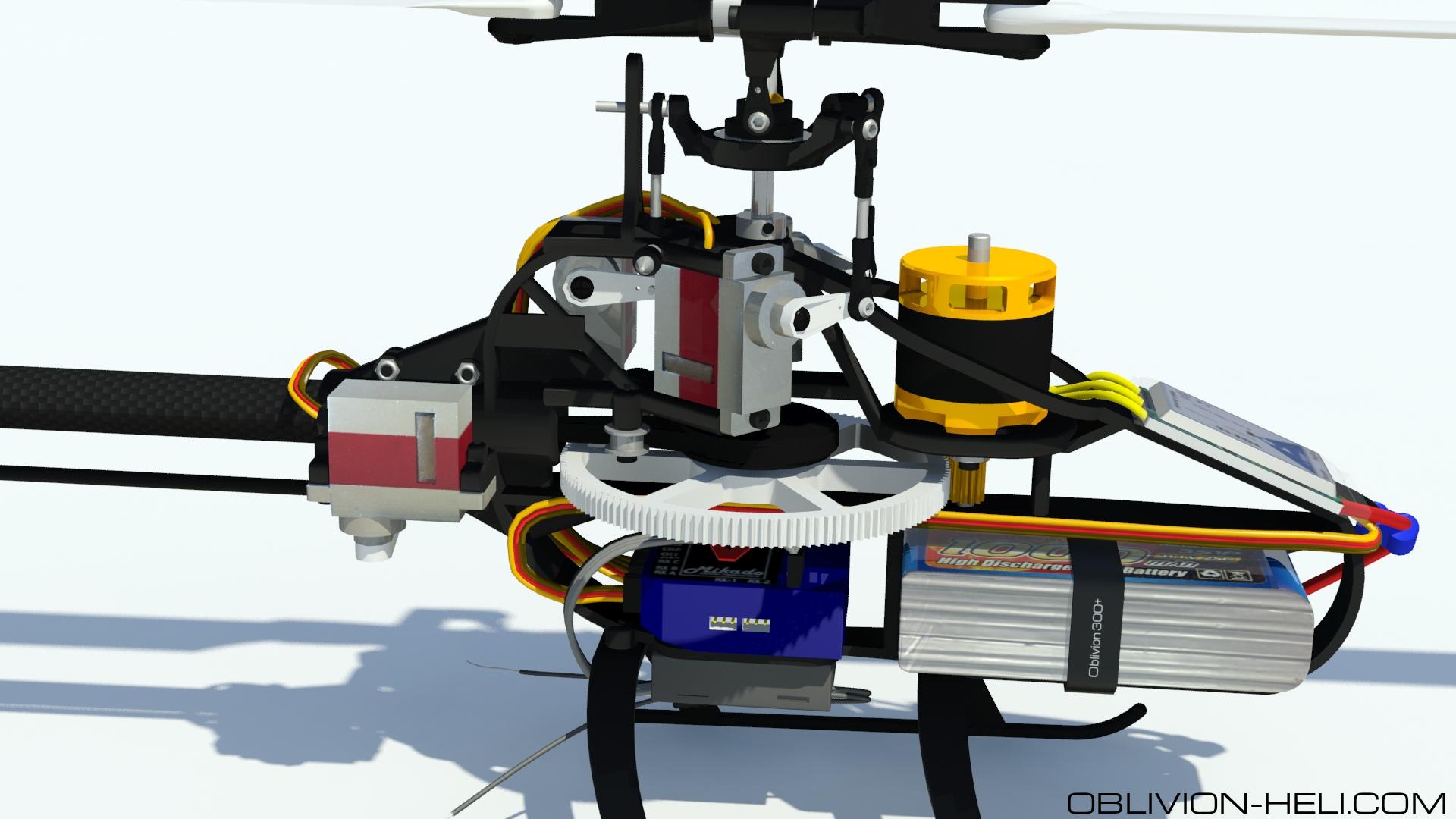

Thanks for all the feedback! First off, we're not ignoring the upper posts, Chris wrote a response to prototype3a and Fauropitotto, he's just waiting for the mods to check it since he's new here. So yeah, spykez, as already mentioned, everything white on this helicopter (except the blades) is sintered. I'll attach you a close up of the swash as well vertico.. Considering that there's only one flying prototype on this planet right now which only has as little as 15 flights down, I'm absolutely NOT keen to try out how it crashes  I would imagine the frame to withstand a crash pretty well though, i mostly expect destruction of the main blades, DFC links, skids, and maybe the tail shaft, the rest is either super flexible or too beefy for me to see it breaking anytime soon I would imagine the frame to withstand a crash pretty well though, i mostly expect destruction of the main blades, DFC links, skids, and maybe the tail shaft, the rest is either super flexible or too beefy for me to see it breaking anytime soon Luigi, yeah, the tail ratio could be better though. The sintered blade grips will be longer, and therefore allow for more airflow velocity over the blades, will check what the minimum tail blade size for appropriate performance will be then. Something about the whole microheli thing: even though we always liked microheli.com parts on our micros, our homepage is microheli.net, which makes a huge difference. microheli.net is Chris' homepage where we post non-commercial reviews and news about our flying club. That they have the same name is entirely coincidental. Lastly, about the material. The parts were designed with the material parameters of the SLS plastic in mind, other materials with comparable weights and tensile strength could work as well, but we didn't test anything but the SLS plastic. And since you managed to write three new posts while I wrote this one, about the servos as well: I chose the KST 115 for this helicopter because this is the very first prototype and I needed something I can rely on, no matter what. It is definitely to save weight using much lighter servos. The reason I chose those was that I ran them in my 450 for over 150 flights and they still perform like on their first day. Just gives me more confidence while flying Aaaaaaand because it was brought up on rcgroups, and I'm Johnny31297, well guess what. WIP.

__________________

Jonas OMPHOBBY M7, M4, M2 EVO & M1 EVO Designing things for Fun-Key RotorTech & OMPHOBBY |

|

|

|

| Sponsored Links | |||

|

Advertisement |

|

||

|

|

#22 (permalink) |

|

Registered Users

Join Date: Aug 2011

|

Haha, thanks, Jonas!

__________________

█▒█ |

|

|

|

|

|

#23 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2012

|

Oh and something I forgot to mention: If the heli seems a little powerless in the 4 minute high rpm video, well, that was (unknowingly) flown without governor at 87% flat throttle!

__________________

Jonas OMPHOBBY M7, M4, M2 EVO & M1 EVO Designing things for Fun-Key RotorTech & OMPHOBBY |

|

|

|

|

|

#24 (permalink) |

|

Registered Users

Join Date: Apr 2012

|

I want one! Have wanted a bigger than micro smaller than 450 heli for my garden for a while now! This is PERFECT, very nice build, I've now decided to try build a similar one myself and making it super light too. Will be hard though as I have no 3D printer, any place that I can get parts printed?

Well done for the amazing work

__________________

Alex Fleet: Miniprotos Flock: cockatiel and congo african grey |

|

|

|

|

|

#25 (permalink) | |

|

Registered Users

Join Date: Aug 2013

|

Quote:

It does look alot like 3d printed stuff though, i'll give you that.

__________________

"Beater" Mini Prôtos stretch 6S : Scorpion 2520-1360kv, Edge 353SE "Princess" Goblin 570 stretch 12S : Xnova 4025-560kv, Cyclone 615 FrSky Taranis - Heli-X 5 - MKS, YGE, SK540 - Yamaha XJ6F |

|

|

|

|

|

|

#26 (permalink) |

|

Registered Users

|

SLS is just a type of 3d printing. It's just the type that requires a ~$10k machine... not your average cheap home printer.

__________________

Jeti DS14us -- TT e700 -- 6s Logo600se UL -- Logo600-3d -- Logo500 UL -- Charge Case |

|

|

|

|

|

#27 (permalink) |

|

Registered Users

Join Date: Nov 2014

|

On a side note. It is really not expensive. Blade grip 4 bucks, fin tailbox 8 bucks... chassis by far the most expensive with 50 bucks. shapeways.com should work out well for most folks I guess.

|

|

|

|

|

|

#29 (permalink) | |

|

Registered Users

Join Date: Nov 2010

|

Quote:

The most common form is FDM (fused deposit modelling) or FFF (fused filament fabrication) which entails extruding plastic. This is the typical method used in DIY home printers like Makerbot, etc. SLA (stereolithography apparatus) uses a liquid polymer which is hardened wherever the special light hits it. SLS (sintered laser selection) or SLM (selective laser melting) uses a laser to bond the 3D printing medium together. EDIT: And if I had read the previous 2 posts, I would have seen that this was already pointed out…

__________________

There are 10 types of people in the world... those who understand binary numbers, and those who don't. |

|

|

|

|

|

|

#30 (permalink) |

|

Banned

Join Date: Sep 2012

|

I'm in need of a new frame, how do you go about paying them and do they have the file on hand already? criz said the chassis was going to be $50, what about shipping? and figure the chassis includes all mounting points so no bearing and tail blocks are needed extra, extra$

There's a few points I would like changed but my 300 can do with one of those chassis atm. |

|

|

|

|

|

#31 (permalink) |

|

Registered Users

Join Date: Aug 2011

|

What did you guys use to design it on, by the way?

Don't tell me you guys did it on 3DS max 2012!!! I'm still trying to learn that in my spare time to cook up some RF stuff!

__________________

█▒█ |

|

|

|

|

|

#32 (permalink) |

|

Registered Users

Join Date: Nov 2014

|

@ spykez: i am using open source freecad for parametric modelling. steep learning curve, but as good enough for what i am doing.

@ Icanfly: check out shapeways yourself, upload the STL and get all info you need. yes, all mounting flanges, holes, bearing housings etc there. to build the chassis this is the only part you will need, except canopy pins - which i designed to break off if required. i would really like to know which canopies are compatible here. jonas has designed a pretty cool shape i think, and i added my painting to it. but i am pretty certain a few other canopies at the market will work well with slight modification. please note that modifications are challenging if you would like to get a good flying heli out of it. disc load is a key factor, so shorter blade grips will increase that. also, swashplate is 140° and even the type of servo arms is optimized in position to have a straight vertical linkage (arm needs to be 13mm). i am not saying any change will have a negative impact instantly, i am saying: i would not take the project for anything else than it is. also, maximum compatibility with existing helicopters was not a design goal. so i really have no clue how any single parts will perform in other helis. for now, that is the setup chosen for this project.  |

|

|

|

|

|

#33 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2012

|

spykez, I actually used 3DSMax for design elements of this helicopter, aka canopy, skids and tail fin

And for the 3d modeling freaks (yay): this model has roughly 650.000 triangles

__________________

Jonas OMPHOBBY M7, M4, M2 EVO & M1 EVO Designing things for Fun-Key RotorTech & OMPHOBBY |

|

|

|

|

|

#34 (permalink) |

|

Registered Users

Join Date: Jul 2011

Location: Colorado Springs

|

I think there is a heli company somewhere that accidentally let a few engineers out of the bag!

Seriously guys great work.  I plan to start building one very soon. I plan to start building one very soon.One idea, you could send the Canopy specs off to Canomod who could make it available to purchase on their website. Just a thought Also, on the website I think it would help if the SLS files were either given version number or dates (or both) IE v2015.06.01 to help be able to identify when new files are available. Also a change log detailing any changes that are made to the pieces when be nice too Why not design SLS plastic grips for the tail instead of the Align metal tail grips? Seems like it would be lighter?

__________________

Fusion 180 - M2 Evo - RAW 420 - Fusion 550 - Tron 5.5 - Kraken 580 - Kraken 580n - Kraken 700 - Kraken 700n - Vcontrol Evo |

|

|

|

|

|

#35 (permalink) |

|

Registered Users

Join Date: Apr 2012

|

Have you uploaded the blueprints? If so in what format?

Amazing work guys!

__________________

Alex Fleet: Miniprotos Flock: cockatiel and congo african grey |

|

|

|

|

|

#36 (permalink) |

|

Registered Users

Join Date: Nov 2014

|

hey vertico, thanks much! i can assure you that both jonas and myself are doing something entirely different for living than this

i do not know canomod, but for sure will check it out. we do have the canopy as stl, both half sides. we also have it SLS printed. the plan was to build a box that would form hot polycarbonate layers to shape (what on earth is the english word for "tiefziehbox"? versioning, yes, i do that internally, and i always only have the latest files uploaded. but i think i will add version numbers to keep a good overview publically as well. thanks for the feedback. if you take a closer look, you will see that i already uploaded tail blade grips for SLS  there are some substancial infos missing on the website. all mechanical drawings, parts list for bolts and nuts, building tutorials etc etc. i am on it, but it takes some time. |

|

|

|

|

|

#37 (permalink) | |

|

Registered Users

Join Date: Aug 2011

|

Quote:

Or maybe it is already in secret production in fibre reinforced plastic?

__________________

█▒█ |

|

|

|

|

|

|

#38 (permalink) | ||

|

Registered Users

Join Date: Apr 2011

Location: US

|

This is pretty cool! They claim this technology can use ANY polymer and is vastly faster with no layers and better strength characteristics than other 3D layering methods. I love the fact it was inspired by the T1000 in Terminator 2

__________________

Mark Dusty Shelf queens: TDR2, TDR, Protos Max, Logo 550SX, Protos 500, Jeti DS-16, etc.... |

||

|

|

|

|

|

#39 (permalink) |

|

Registered Users

Join Date: Jul 2011

Location: Colorado Springs

|

Curious, where is the main shaft sourced from?

I see it in the list of parts needed but it does not specify

__________________

Fusion 180 - M2 Evo - RAW 420 - Fusion 550 - Tron 5.5 - Kraken 580 - Kraken 580n - Kraken 700 - Kraken 700n - Vcontrol Evo |

|

|

|

|

|

#40 (permalink) |

|

Registered Users

Join Date: Aug 2011

|

I was going to suggest mabe to incorporate some kind of carbon fiber backbone into the frame for lateral support, but when I see the freakin 3D printed swashplate there seems to be no problem with stiffness.

Have you guys made some build pics by chance? Would love to see the naked frame in a pic. Another question: Is it possible to stack the smaller parts of the heli into the frame openings for printing? Could save a few bucks when printed as one part, at least that´s the offer on https://www.3dprint-uk.co.uk/portfolio/pricing/.

__________________

2x MCPX I Gaui »X1« I 2x Mini Protos I Protos I DX8 |

|

|

|

|

| Tags |

| oblivion 300, oblivion 300+, oblivion heli |

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

1Likes

1Likes

Linear Mode

Linear Mode