|

START HERE |

|

| Register | FAQ | PM | Events | Groups | Blogs | Calendar | Mark Forums Read |

|

Unregistered

|

||||||

| Electric Motors Winding and Repair Electric Motors Winding and Repair Discussion |

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

#1 (permalink) |

|

Registered Users

Join Date: Dec 2004

|

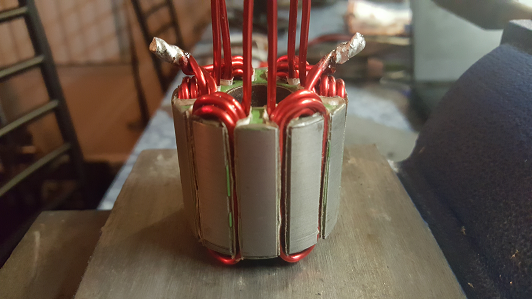

Hi all,

While doing maintenance to my 800MX motor, I found the stator bearing needed replacement. When I was removing the stator bearing, the stator moved out of the stator carrier some millimeters. I moved the stator back to its place, but now I noticed I can make the stator rotate in the stator carrier if I apply force with my hand. I see the stator has an anti-rotation slot so this shouldn't be happening. I believe moving the stator broke the retaining compound or something. I also found the bearings being used in the motor are Japanese 6800z bearings. The shaft is fine so I would buy the bearings and not the bearings/shaft kit Align sell. Where can I get these Japanese bearings? What can I do to fix the stator/stator carrier issue? Thanks, David

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

| Sponsored Links | |||

|

Advertisement |

|

||

|

|

#2 (permalink) |

|

Registered Users

|

I like to drill/tap mine and install a M2 screw.

__________________

Jeti DS14us -- TT e700 -- 6s Logo600se UL -- Logo600-3d -- Logo500 UL -- Charge Case |

|

|

|

|

|

#3 (permalink) |

|

Registered Users

Thread Starter

Join Date: Dec 2004

|

Ok, thanks.

Does this motor come with a pin in the stator carrier from factory to prevent rotation of the stator?

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

|

|

#4 (permalink) |

|

Registered Users

|

I would expect it to have one but I've never actually had a 800mx in my hands.

__________________

Jeti DS14us -- TT e700 -- 6s Logo600se UL -- Logo600-3d -- Logo500 UL -- Charge Case |

|

|

|

|

|

#5 (permalink) |

|

Registered Users

Thread Starter

Join Date: Dec 2004

|

After thinking about what happened, I've decided to leave the motor as is. The stator moved a bit and it wasn't rotated when it was moved, so nothing should had broken. I believe it came from factory that way so I hope it works fine after I put it back. It's possible I do more harm drilling/tapping it.

Thanks for the help.

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

|

|

#6 (permalink) |

|

Registered Users

Join Date: Oct 2006

|

You should insert a pin. If you don't you risk damage to motor and esc. Stock there is no pin and sometimes the motors come apart too easily.

In stead of tapping I suggest the following: With a dremel cut off disk, cut a shallow groove in the side of the stator carrier along approx 15mm length. Goal is to create a channel for a 1.5mm diameter drill, so it does not have to remove as much material. Be careful not to drill too deep as the drill chuck could touch the windings. Use epoxy when putting the stator carrier back in the motor and insert a 10mm long 1.5mm dia piece of piano wire in the drilled hole.

__________________

Raptor E700: PowerDekker Pyro650, JR DS8925HV & SPG01, 12s, Vortex VX1, Kosmik160, Jeti DS-16 Last edited by _Dekker; 07-24-2014 at 03:50 PM.. |

|

|

|

|

|

#7 (permalink) | |

|

Registered Users

Thread Starter

Join Date: Dec 2004

|

Quote:

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

|

|

|

#8 (permalink) |

|

Registered Users

Join Date: Oct 2006

|

Yes. But first do a loose fit without glue and drill. After that glue and insert pin.

__________________

Raptor E700: PowerDekker Pyro650, JR DS8925HV & SPG01, 12s, Vortex VX1, Kosmik160, Jeti DS-16 |

|

|

|

|

|

#9 (permalink) | |

|

Registered Users

Thread Starter

Join Date: Dec 2004

|

Quote:

Does drilling the stator core plates affect the flux due to the conductivity now imparted by the drilling process and pin installed? I ask this because the stator core is made of sandwiched plates that are electrically isolated from each other to reduce the eddy current looses.

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

|

|

|

#10 (permalink) |

|

Registered Users

Thread Starter

Join Date: Dec 2004

|

Wow, how come they design motors like that with such imminent risk?

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

|

|

#11 (permalink) | |

|

Registered Users

Thread Starter

Join Date: Dec 2004

|

Quote:

As you stated, no anti-rotation pin in the stator carrier. I removed the stator from the stator carrier with my hands. I can't understand how these motors operate without the anti-rotation pin, and seems isn't an issue. The stator even didn't have any evidence of glue or retaining compound applied to it. It's disappointing to see the lack of quality inside the motor. Thank you very much for the help guys.

__________________

T-Rex 700E Pro DFC, Spirit FBL Unit, Futaba R6303SB/8FGHS Blade mCPx 140mm boom, DX7 RealFlight 7 |

|

|

|

|

|

|

#12 (permalink) | ||

|

Registered Users

Join Date: Jul 2006

|

Old thread, I know, but how do you actually disassemble this motor? I need to change the shaft on mine, and have taken the two grub screws out, but I can't separate the two can halves. I've seen this video for a scorpion motor, below, but there is no circlip on the align motors etc.

I've seen this method, but to me, heat and magnets are not things I'm keen to mix. I know the motors can get up to canny temperatures in flight, but not 200C! https://www.bocabearings.com/rc-heli...-align-bl700mx

__________________

Harry Thunder Tiger Raptor E720 CGY750 | Mikado Logo 700 CGY760R |SAB Kraken 580 CGY760R| Powered by Futaba 18SZ |

||

|

|

|

|

|

#13 (permalink) |

|

Registered Users

Join Date: Nov 2012

|

Same as the video except you can't take the stator out first. I've never used heat but motor magnets are generally rated for very high heat anyway. That video is ok but he makes it out to be a bigger deal than it needs to be.

Are your bearings already bad? Because pressing it out with the stator still installed will probably ruin the rear bearing. I always bought Scorpion or Xnova shafts if I had to take apart an Align, so I didn't have to deal with the problem of pressing it in and out every time to disassemble.

__________________

Protos Max Leggero 700, Logo 600SE, Blade 230s DX9 |

|

|

|

|

|

#14 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

If you dont want to scribe a keyway with a dremel which isnt that exacting but works you can simply clue the stator to the carrier like the factory had attempted with 609 loctite. It wont go anywhere.  I used it on my high current align because i did not want to scribe a keyway with a dremel. This is what its for. Painless. |

|

|

|

|

|

#15 (permalink) | |

|

Registered Users

Join Date: Jul 2006

|

Quote:

I've just had the motor in the oven at 200C for 10 mins, and it's not budging. I was hoping it would be like a nitro engine where the bearings just fall out, but alas no. I've obviously taken out the two grub screws, but this motor is still solid... So much so that I fear trying to use an arbor press will damage the can.

__________________

Harry Thunder Tiger Raptor E720 CGY750 | Mikado Logo 700 CGY760R |SAB Kraken 580 CGY760R| Powered by Futaba 18SZ |

|

|

|

|

|

|

#16 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

I think that may be a little too hot. To drop em out a nitro engine about 220°F on the aluminum nitro engine block. If you are going to replace them and dont care about the bearings u can knock them out with a loose dowel.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

1Likes

1Likes

Linear Mode

Linear Mode