|

START HERE |

|

| Register | FAQ | PM | Events | Groups | Blogs | Calendar | Mark Forums Read |

|

Unregistered

|

||||||

| Electric Motors Winding and Repair Electric Motors Winding and Repair Discussion |

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

#1 (permalink) |

|

Registered Users

Join Date: Nov 2015

|

So as the winding factor increases for single layer to dual layer winds what happens to the tooth flux density? I assume that if a stator core was designed for dual layer winding, tooth flux density would go up when it is rewound for single layer. It would seem that there is a high possibility for core saturation and loss of commutation..

In dual layer winding Is flux density shared between paired teeth? It my be that Chinese BLDC motors use CRS instead of Si lamination for cost reasons. So winding them for single layer winding is risky. |

|

|

|

| Sponsored Links | |||

|

Advertisement |

|

||

|

|

#2 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

The Castle Hydra Ice hv 200 v2 never had an issue running my China iron.The self inductance of the single layer machine is generally double and the mutual inductance is generally half the of a dual layer machine, the single phase sector, or SPS. The single layer machine has more torque density.It is better suited toward drives that utilize trapezoidal algorithms and will show less ripple with them.

Last edited by 1BOHO; 02-10-2020 at 09:20 PM.. |

|

|

|

|

|

#3 (permalink) |

|

Registered Users

Join Date: Oct 2011

|

Das Problem ist altbekannt.

Hast Du evtl. mal in Erwägung gezogen, dass dieses Problem nicht nur mit dem Material an sich, sondern auch mit dem Align-Statorschnitt mit den vergleichsweise schmalen Hammerstielen zusammenhängen könnte? VG powercroco |

|

|

|

|

|

#4 (permalink) | |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

Quote:

Hi, You have a scope so you can observe the line voltages of the comparative machines. But you can see here these test have already been performed and there's nothing really happening especially in the saturation zone which is on the right with respect to a single or a dual layer that would cause drive instability issues unless the drive ran a sinus algorithm and doesn't like the flatter top bemf or the low mutual inductance.Thin teeth would not create a problem due to saturation because it's wound in a single layer. The tooth thickness would be the same in both instances unless it was an alternating head no head stator. Flux linkage is a result of the tooth's width and hammerless single layer motors run fine with BLDC drives. I don't understand what is meant by alignment to the stator? Flux is maximum at the center of the spokes with or without teeth.High end "Bldc" drives that use "sinus" algorithm like young generation electronics will likely produce less torque and probably suffer more ripple running one and possible runs into instability if it doesn't like lower mutual induction. Each machine observes its respective character into saturation.Those are 2 Bemf plots that show this.The one on the left is neglecting saturation the one on the right is when the stator is saturated. A single layer should run fine with the typical low cost Chinese BLDC drives Last edited by 1BOHO; 02-13-2020 at 08:12 PM.. Reason: addendum |

|

|

|

|

|

|

#5 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

Yes Christian and P901

It isn't about the hammers or tooth width I dont think because the Align certainly isnt special with thick iron though that makes more powerful it runs fine in a single layer without the teeth of the kyocera.. Quite naturally a dual layer machine should have better inductive coupling. In a single layer the with short coils the mutual inductance is much lower. There are practical ways to deal with this and some not so in your face. If you suggest that the Chinese steel is so much poorer that it doesn't generate enuf flux Id say that bs because I truly don't believe that you "higher end motor" use much better at there price point. You would have to see the price of hiperco , sura, and other high end magnetic steel. It would drive you to buy exclusively from hobby king. China even with it's transshipping of raw unfinished steel to other countries the its refined there only supply us with about 4%. Look at these numbers . Last year we imported about 750 thousand tons from China. To put this is perspective we imported 5.7 million from Canada and another 5 million from Europe. Not trying to be political but 45's tariffs hurt our European allies much more than they hurt China. That's just the numbers of it all . The trans shipping in a way means that there is steel floating around out there and after it left its original port no one really knows where it came from. Still I doubt very seriously the difference in grade if there truly is any would create issues. I think the lack of mutual inductance is more about the distance apart in a single layer than the core material wrapped. Better steel would increase the mutual inductance but i just dont think the steel in hobby priced motors all that high end. A neu which is a very efficient motor uses silicon steel. There's nothing really space age there I'm afraid. Most space age steel motors end up in space. Without making or taking any loss measurements calculations you have no idea whats what between stators anyway. You use a Epstein frame or Helmholtz coil and sg to do this or you can calculate if if you know the actually materials used from their specifications sheet. The winding factor is more about the coil span and distribution factors. The phasor vectors than it is about flux. I have never seen flux in a winding factor formula. Some the new winds have better inductive coupling and winding factors than either of it's primitive ancestors. Happy Harmonics, Hubert Last edited by 1BOHO; 02-14-2020 at 10:20 AM.. Reason: addendum |

|

|

|

|

|

#6 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2015

|

If you are in the linear portion of the B vs H curve then you may have a chance of improving performance. But how would you modify an existing machine to get above the knee of the curve and without getting above the saturation area of a unknown steel? You have to assume that all Chinese motors use CRS 1018 steel.

For ease of design probably the linear portion of the B vs H curve was used. So maybe the motor was not designed for maximum efficiency. In an effort to improve efficiency is to increase tooth flux density and get it closer to the material's max flux density. Single layer winding would allow more slot fill and would allow more winding thus increase saturation. So now what is exactly the right amount of winding needed for best performance? And what about input voltage variables? Looks like the solution is experimentation. Last edited by p901p901; 02-14-2020 at 04:10 AM.. |

|

|

|

|

|

#7 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

Well why wouldn't we be able to increase widing factor efficiency and ripple irrespective of saturation? Does a dual layer run more efficiently in the saturation zone ? I wont make any conclusions about what they use for core material without testing the core. U can easily compare the K if u definitively know the materials. I dont think u do. Is the end function after the curve level or ascending? Does this curve change dependent on which teeth are wound ? Does any motor from any nation or any material run particularly efficient after that? All u need is a practical approach. If u know the materials every questions can be definitely be answered but how would u know this for each and ever motor without testing the cores or being the OEM? Input voltage is simple if you lower it current increase to make the same power. It's no experiments needed it's a well documented way to get a drive out of instability issues when LOW MOTOR INDUCTION is an issue. I posted the formula years ago. Another is to increase pwm.

Happy Harmonics , Hubert Last edited by 1BOHO; 02-14-2020 at 07:54 AM.. |

|

|

|

|

|

#8 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

The Effects of Inductance on Motor Performance: Qualitative Discussion | The Ellipsah Blog https://www.rcgroups.com/forums/show...ductance/page2 Edit: Let me make one correction about Rons post about losses. Mathematically you can not use rpm or rpm^2 to make any accurate loss determinations because it is actually frequency dependent and this frequency would be different at the the same rpm with motors of different pole counts. If we used rpm to compare two such motors losses our numbers would come out the same. Happy Harmonics, Hubert Last edited by 1BOHO; 02-14-2020 at 09:12 AM.. |

|

|

|

|

|

#9 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

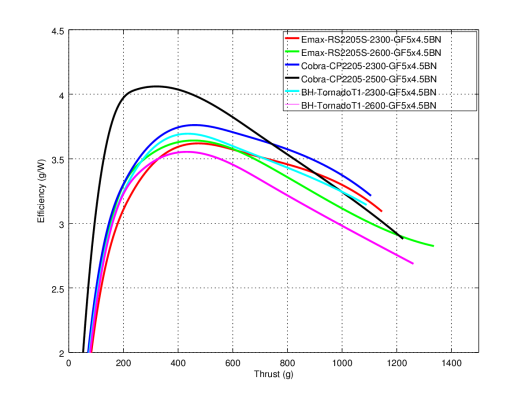

This is what I mean about practicality. A good motor doesnt have to have the best core. A good core not optimized through the rest of the magnetic circuit does nothing particularly special. You see Chinese emaxx here who manufactures a huge percentage of the drone motor market sits here first with maximum thrust output. It was an overall 2nd place over the US Cobra which showed much higher efficiency than all others. Maybe they use a superior core but at the price point I doubt it. I think they've just created a more optimized magnetic circuit. Happy Harmonics, Hubert Last edited by 1BOHO; 02-14-2020 at 09:43 AM.. |

|

|

|

|

|

#10 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2015

|

Thanks for the information.

I was thinking about getting the most use of the iron without going into over-saturation. It seemed that not winding one tooth was not the best way and 2 layer winding was the way to go. Two layer winding were one tooth was wound with different number of winding's seemed also odd. CL mentioned that in single layer winding that the unwound tooth was to close the magnetic circuit.I guess it time to study more about electro-magnetism. Thanks again. |

|

|

|

|

|

#11 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

.....double post

Last edited by 1BOHO; 02-15-2020 at 03:26 AM.. |

|

|

|

|

|

#12 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

Well by design should n't the density be about half neglecting leakage on the dual layer? Only half the coil is there with half the self induction on the individual teeth. You cant get more out of the iron than whats there. You can reduce its loss though but in a sense the iron is just carrying what's there which in the single layer has to be nearly double.The dual layer hue on center is about half the single. So its flux is about half. Makes perfect sense to me what you see here. In theory The single layer is also going to run better with a 6 step drive. The new winds FEMM would look better than either and yous see how the core loss is improved.

|

|

|

|

|

|

#13 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

Did you actually do a comparison between single and dual layers? After a second look it seems this is just a saturated and unsaturated comparison. Is that correct? The one thing that comes to my mind is the single layer with the higher winding factor is a more efficient producer or torque so in theory it should produce the same amount as a dual layer with less amperage. |

|

|

|

|

|

#14 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2015

|

I did not know how to embed the pictures and add comments to them.and I did not try single layer winding.

The pictures are from the motor I built using Emetor design software. I had to increase the tooth and hammerhead width to prevent over saturating the stator. Also found out air gap and magnet strength also reduced saturation. On the test bench using 10 cells the motor would loose sync around 5kw and 7.5K rpm. With 8 cells the motor works fine. Motor is very strong and been using it for over two years. Magnets were not high temperature so they are getting weak. I always thought the reason for it cutting out was from oversaturation. Advancing the phase and changing the timing did not work. With a 55% fill factor I do not think this was not an amps per turn problem. So I ruled out under saturation problems. . |

|

|

|

|

|

#15 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

If it runs fine as soon as you lower the bus voltage it sounds like induction may be something to look at.Things to try. First bump up the PWM frequency and see if stability returns. Second, put more load on the motor and see how it responds. I'm still trying to locate the formula I posted some time ago. It explains the relationship. Let the modeling program examine the sl and dl and show us what that looks like if you don't mind. You can get femm 4.2 for free. You might want math lab too or some type pf graphing calculator. How many custom parameters does the emeteor modeling take? If you want to embed your photos just open the attachment after you upload it then copy the url and place it inside the image tab in the tool bar above. You can center it using the margin options in advanced mode. Sometime you have to open it in paint reduce the size and re save it. See how its just a little too large?

Last edited by 1BOHO; 02-16-2020 at 04:49 PM.. |

|

|

|

|

|

#16 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

|

|

|

|

|

|

#17 (permalink) | ||

|

Registered Users

Thread Starter

Join Date: Nov 2015

|

Emoter ended about 3-4 years ago. Right now I am trying to use Motoranalysis-pm to try different configurations. This program requires an import of a .dxf file for the rotor. The problem I have is that the imported drawing fails while opening into the design page.

It looks like any changes to the rotor design require a reedit of the cad file. Emoter was much simple. The motor is in a F-84F-Thundersteak it flew a few times and has been in storage for over a year.

Thanks for showing me how to embed pictures.It will make things much better. Take care. |

||

|

|

|

|

|

#18 (permalink) |

|

Registered Users

Join Date: May 2014

Location: Research Triangle Park

|

That's really great. Its a 14 pole. .Any photos? Where did you get your laminations?

Thanks Hubert, |

|

|

|

|

|

#19 (permalink) |

|

Registered Users

Thread Starter

Join Date: Nov 2015

|

Laser lamination made them https://laserlaminations.com/. I had 150 made and they ended up in 2 projects. About $1 each and another $50 for setup.

Lamination 8 cell test This is what they came from https://www.helifreak.com/showthread.php?t=722591 |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

2Likes

2Likes

Linear Mode

Linear Mode